“Before the COVID-19 pandemic, people didn’t fully realize how essential oxygen was in the management of severely ill patients. The pandemic opened everyone’s eyes. Oxygen has been, and will continue to be, life. “We learned this the hard way.”

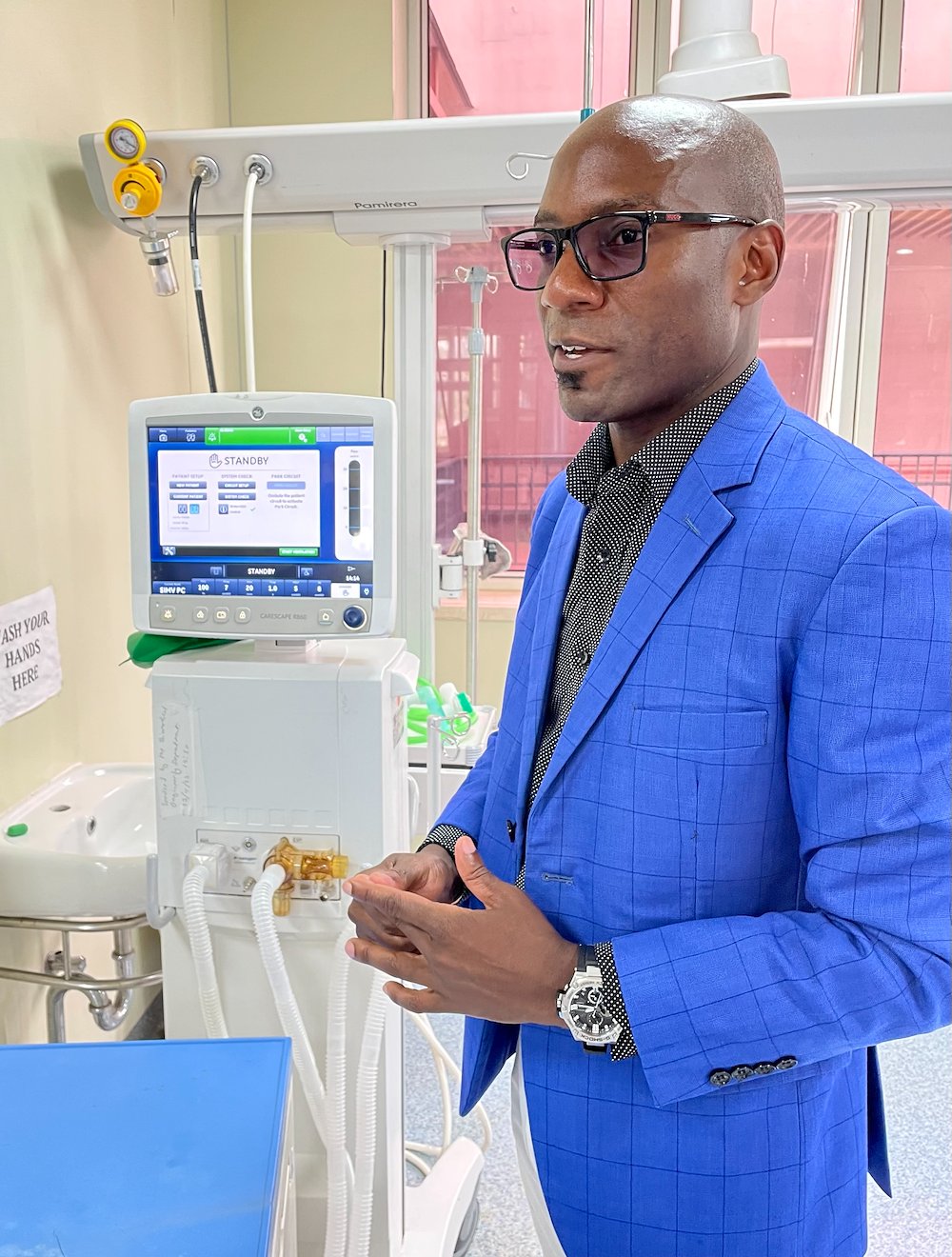

When COVID-19 hit, Joseph Mphande was working as a biomedical engineer at the Levy Mwanawasa University Hospital in Lusaka, Zambia’s second largest health facility. The hospital was the only one in the country with a functional pressure swing adsorption (PSA) plant capable of producing medical grade oxygen to deliver the gas to patients.

“It happened so fast,” said Mphande. “We had two patients with COVID, then 10... The numbers continued to shoot up. The next thing we saw was that the hospital became the country’s main COVID center. But we couldn’t keep up. The electrical grid was unstable, and we could have power cuts which affected the PSA’s plant capacity to generate oxygen. When the electricity cut out, people would shout, ‘there’s no oxygen!"

Mphande and his colleagues supplemented the PSA plant with procured oxygen cylinders, but it wasn’t enough. Each cylinder only lasted 40 minutes, as each patient consumed as much as 60L to 70L of oxygen per minute. The PSA plant could only generate a capacity of 450L per minute; sometimes, due to the number of patients using large volumes of oxygen, the PSA plant failed to meet the demand.

There are three ways to produce medical oxygen: oxygen concentrators, small, portable systems that sit by a patient’s bedside and produce oxygen for one person at a time, but can only offer low pressure oxygen flows of up to 15L per minute; PSA plants, very large, complex oxygen generators that require high amounts of electricity and pressure; and air separation units (ASU) that produce bulk liquid oxygen, which is stored in large tanks and then vaporized to gaseous medical grade oxygen and fed into a hospital system. Liquid oxygen produced by ASU plants is seen as “best-in-class” and is most commonly used in countries with robust health care facilities.

When COVID hit, Mphande had just returned from a six-month medical equipment training in China, where he learned how to operate and maintain bulk liquid oxygen systems. Overall, liquid oxygen offers higher purity and more efficient storage, and is easier to use and more reliable than other oxygen sources. On a per-unit basis, liquid oxygen is also 20% less expensive than medical grade oxygen produced through PSA plants.

As part of Unitaid’s response to the COVID-19 pandemic, the Ministry of Health worked with the Clinton Health Access Initiative (CHAI) to install a new liquid oxygen tank at the Levy Mwanawasa University Teaching Hospital. Today, the hospital is running the bulk liquid tank alternately with the PSA plant to ensure an uninterrupted supply.

“It’s still difficult to talk about what happened during the pandemic. I know we saved so many lives, but we can’t replace those we lost. With the liquid oxygen system, if we have another pandemic like COVID, we won’t go through this again,” said Mphande. “And for the patients who need oxygen every day to soothe their breathing, we can provide it.”

Mphande is now the National Oxygen Coordinator with Zambia’s Ministry of Health. He led the development of the country’s new National Medical Oxygen Strategic Plan (2022 to 2026), which calls for the use of bulk liquid oxygen to strengthen patient care and respond to health emergencies. Under the new plan, all high-volume health facilities are encouraged to have bulk liquid oxygen systems with a back-up PSA plant.

Building sustainable, reliable and affordable access to medical oxygen and oxygen equipment in low- and middle-income countries is one of Unitaid’s priorities. Through Unitaid’s market-shaping approach, Unitaid works with partners to introduce innovations such as better quality, more affordable oxygen delivery systems; strengthen health security by building regional oxygen production capabilities; create healthy competitive markets by negotiating lower prices with existing suppliers; and facilitate skills transfer and training for emerging suppliers to meet quality standards and further lowering prices and creating more competitive markets. We’re also supporting governments and health facilities to determine the most appropriate oxygen system for their needs.

This kind of support is urgently needed, said Mphande.

“To implement our national plan, we need to expand liquid oxygen tanks to more facilities. We also need to break the monopoly on liquid oxygen so we can lower prices,” he said. “Liquid oxygen can level the playing field when it comes to oxygen and service delivery.”

In response to the COVID-19 pandemic, Unitaid immediately provided flexible financing and delivered emergency oxygen supplies to 51 low- and middle-income countries. We also played a leading role in the Access to COVID-19 Tools Accelerator (ACT-Accelerator), a groundbreaking collaboration to ensure equitable access to COVID-19 vaccines, tests and treatments. As co-lead of the ACT-Accelerator’s Therapeutics Pillar, together with the Global Fund to Fight AIDS, Tuberculosis and Malaria and Wellcome, we launched the Oxygen Emergency Taskforce to address the critical shortage of oxygen in the fight against the pandemic. The taskforce raised more than US$1 billion to boost access to medical oxygen, expand production, negotiate for better pricing, and provide technical advice to governments.

To learn more about how we are working to increase sustainable access to medical oxygen, read our issue brief.

© 2024 Unitaid